How To Build A Fly Rod

Jeff Day shares his insights into the challenging craft of building a bamboo wing rod.

I've been a woodworker and a fly fisherman for years, so it was probably inevitable that sooner or later I would build a bamboo fly rod.

Inevitable, maybe, just non necessarily a walk in the park. It cost me a fishing season. I broke rods long before they left the shop. I made rods that worked better as tomato stakes. I fried one rod to a crisp. I suffered epoxy failures and polyurethane busts. In brusque, I enjoyed every minute of information technology, and iii rods after I started, I have a rod that I'thou not aback to show to the globe. It would accept gone better if I had learned to follow directions at some point in my life, just it'south besides belatedly for that. I will never be a legendary rodmaker, but I hope I tin can save yous from some beginner'south mistakes – maybe all of them – in this article.

But allow'southward first at the kickoff. A bamboo fly rod is made of 6 strips of bamboo glued together to class hexagon (photo beneath). The strips are triangular in cross-section, and since the rod tapers from handle to tip, the triangular strips taper, too — the triangle is bigger at ane cease of the strip than the other.

All of this is washed in three stages: Commencement you rough out a rod bare, splitting the bamboo stem to stern, kiln drying it, then planing information technology into long triangular strips — a gear up of vi strips for each section of the rod. In the 2nd stage, you taper the triangular strips with a cake plane and a special metallic grade. Then yous gum the pieces together, clamping the pieces together by wrapping them with thread. On a proficient day, information technology'south a like shooting fish in a barrel. On a bad day, it's worse than getting skunked on the stream. Far worse. The concluding stage is applying the end and attaching the hardware. I like to think of the stages every bit lumberjack, cabinetmaker and finisher.

Stage I: Lumberjack

This stage begins with a slice of Tonkin cane, the but cane used in rod making, considering its long, dumbo, fibers make for a powerful rod. In the entire world, Tonkin cane grows in a single 30-square mile patch of China. When merchandise with Red china was banned during the Cold War, the but dealer who withal had any cane left was Charles Demerest, in Bloomingdale, New Jersey. From 1950 to 1971, his pre-embargo bamboo was the rodmaker's only supply. Demerest is still one of the few suppliers in the country, and I buy my cane from him because he kept a tradition alive. His bamboo, like all Tonkin cane, is sold in 10-human foot lengths, which are ordinarily cut in one-half for aircraft.

Technically, bamboo is a grass, and a stick is called a culm. The easiest and fastest style to become the strips yous need is to split the culm the way Windsor chair makers rive a chair back from a log, and for the same reason. Splitting bamboo gives you a piece with long parallel strands of grain. Rodmakers often make their own splitters out of knives or screwdrivers that they drive into the end of the culm. Mine are chisels with edges that are ground to a rounded point. As the pieces go smaller, I hold the stop of the chisel on the demote with i manus, and feed the bamboo into information technology with the other. Your goal: six strips plus whatever else you can get from the bottom five anxiety of the culm. This will be the butt section. The tip comes from the upper five anxiety of the culm, and because rods traditionally have an extra tip, you'll want to divide it into 12 pieces.

At this indicate, you make a couple of minor adjustments. A stick of bamboo is divided into shorter sections by a serial of bumps, called nodes. You need to get rid of the bumps and deal with the bends that typically occur around them. Fortunately, bamboo bends when heated. Holding the node directly over a heat gun (photo below) until the forest is almost too hot to handle makes the heated section curve like warm plastic. In one case yous've heated it, you tin flatten the node completely (or well-nigh so) by clamping information technology in the vise with the outside confront against a jaw. Count to 10, and then clamp the edges between the jaws to straighten out the bends. If any of the nodal bump remains, yous sand it out past hand with 240-grit paper and a hard safety sanding block.

Before nosotros shape each piece into a triangle, there are ii steps. The first is to become each piece downwardly to a manageable width. Traditionally, this is done with a hand aeroplane — it may be a grass, but bamboo works like wood. Tradition has its place, but this isn't actually the time for it. I rip the strips to width on the table saw (use lots of featherboards) and and so I aeroplane them into triangles on jig in the planer (photo below). The planer jig is a unproblematic oak auxiliary table with 60-caste grooves routed into information technology. Battens on the bottom fit snugly against the front and back of the planer bed to hold the jig in place. Each groove is slightly shallower than its neighbor — the largest is about 3/8 inches deep and the smallest is nigh 1/sixteen-inch deep. I feed all the strips into the first groove, flip them edge for edge, and and so feed them into the next shallower groove. I work my way downward the table until I've planed the strips to the size required by the rod.

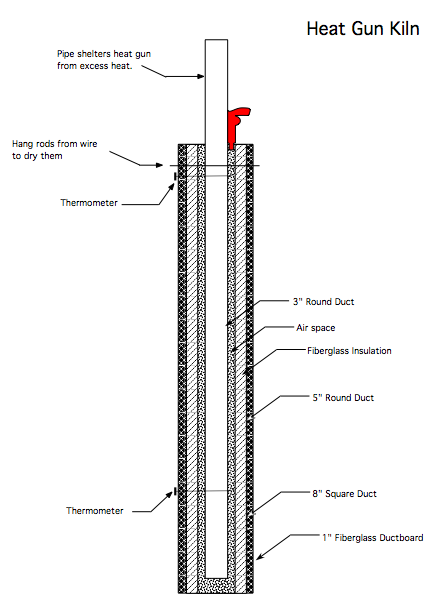

Like any piece of lumber, your strips of bamboo need to be kiln dried. This non but drives out h2o that might haunt yous down the road, it tempers the bamboo, turning what would otherwise exist a soft rod into i with backbone. It doesn't accept long — nearly 10 minutes at 350 degrees for the butts, and slightly less for the tips. The trouble, of course, is finding an oven that will hold a strip of bamboo that is still somewhere between four and five feet long. Some people make friends with the folks at their local pizza shop. The electric current rage is a store-built oven with a thermostat and electric heating elements mounted inside metal heating duct. (It was on a rough variation of this that I baked a rod into charcoal.) I now utilize a heat gun, combined with a couple of heat ducts — one within the other — with lots of insulation around the outer pipe (photograph and diagram below). The heat gun shoots rut down the exterior duct; it rises into the inner duct at an even temperature. I apply ii meat thermometers, one at the acme and one at the bottom of the ducts to monitor the temperature. I'm lucky: the unit automatically tops out at nigh 350 degrees, but if necessary, I can regulate the temperature by adjusting the air intake on my rut gun.

Stage 2: Cabinetmaker

Here, tradition rules, I am fine with information technology. You are working with a finely tuned plane, a razor-abrupt blade and a tapering jig that adjusts to the thousandths of an inch. I enjoy information technology the way I relish fly casting—aught matters but what you're doing, and what yous're doing is well-nigh every bit good equally it gets.

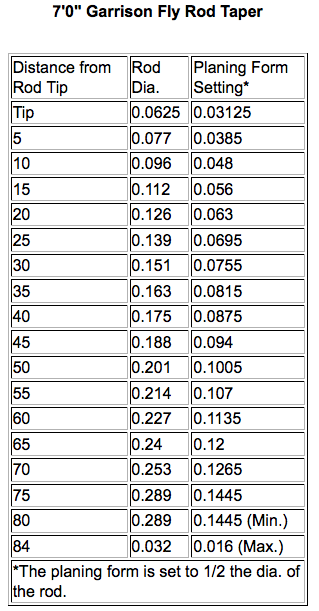

The fact is, that while there is no perfect taper for a rod, there are thousands of bad ones. I chose a time-tested taper developed past Everett Garrison. Garrison made some 700 rods from 1927 until his death in 1975, and they are considered some of the finest ever made. I copied the seven-foot rod he used on the last day he went fishing. The dimensions are listed in the nautical chart (see below) seven'0″ Garrison Fly Rod Taper. Some of his other tapers, likewise as his directions for edifice can exist found in his book A Master's Guide to Building a Bamboo Fly Rod, co-authored with Hoagy Carmichael.

Understanding how rodmaking works means understanding how the tapering jig works. The tapering jig, also chosen a planing form, is fabricated of two confined of steel v anxiety long. The edges that confront each other are chamfered and form a V-groove when the confined are put together. At one finish of the jig the chamfers form a deep valley; at the other end they form a shallow valley. In between, the chamfer forms a valley that slopes evenly between the ii ends. The bamboo sits proud of the jig, and you plane it until the airplane is riding on the jig. When it is, the bamboo is the same shape as the valley—wide at ane end, narrow at the other. Because of the hundreds of different rod tapers, you tin can adjust the depth of the valley every five inches using a pair of bolts. One commodities pushes the metallic bars farther apart, the other pulls them together.

Setting the Planing Forms

Setting the forms to the proper taper requires two tools from the machinist's trade — the dial caliper and a depth indicator with a pointed tip (above). Initially, you set the forms with a depth judge, and afterward planing a test strip, you cheque the setting's accuracy with the dial caliper.

On the face up of it, setting the planning forms to get the taper yous want is a affair of tightening and loosening a serial of bolts. The problem comes in knowing how much to tighten or loosen them. For this, yous rely on a machinist's tool, called a depth judge, which reads out the depth of a hole in thousandths. Because you lot're measuring a V-groove, you put a 60-caste tip on the cease of the gauge.

But considering of the fine calibration involved, machinist tools have to be "zeroed out. " On a dial caliper, your bring the jaws together, loosen the lock on the punch, and and then turn it so the needle is pointing exactly at null. For a lot of reasons, this is tricky with a V-point tip, and unless your setting is accurate, y'all tin't very well adjust the forms.

Here'southward the solution. Zip out your dial caliper and then prepare the opening betwixt the jaws to .100. Put the dial indicator between the jaws, and turn the dial until information technology reads .866. Lock the dial in place, and y'all've calibrated the depth gage. You'll note the wooden base of operations on my depth gauge. The threescore-degree tip is a bit wide, and catches on the metallic base of operations that came with the indicator. A lot of rodmakers use wooden bases, and until I get effectually to buying a new tip, I will, too.

But depth gauges are like fishermen. They aren't always truthful. Set the forms .003 inch wider than called for, and plane a spare strip of bamboo. Check the size with your calipers, and adjust the forms until your sample and your calipers tell you you've got it right.

As you plane, always go on the outer face of the bamboo, chosen the rind, against a chamfer, so that y'all don't cut through the fibers there, which are the strongest. Alternate planing between the remaining two sides with every pass, so yous don't aeroplane more off one side than the other and end upward with asymmetrical strip. Mensurate with your dial calipers as you go, and if the sides differ, airplane the short side until they are equal. One time you've planed the butt sections, reset the jig for the tips, and plane abroad.

A Custom Congenital Rodmaker's Airplane

At some indicate early on in your rod building, the edge of your aeroplane will dig into the planing forms you've but spent a small fortune to buy. Everyone does it, and no one likes it. Merely special rodmakers' planes give you the control you need to avoid gouging. They accept a groove milled downward the middle, creating two outside "track" that glide along the form. The groove travels over the bamboo, and the blade extends just far enough to exercise its work without cutting into the planing form. I don't always use the plane, but when I do, information technology is nigh impossible to gouge the planing form.

The simply rodmaker's aeroplane on the market place is a beautiful piece of work, just yous'll pay for it. Instead, I made my ain past routing a groove through a favorite block airplane. I used a 5/viii-inch directly bit in the router table, and fix the distance between the flake and runway to 1/two inch– the width of a rail. Heighten the router flake to make a cutting near .001 deep and brand a trial run on a piece of wood to check your setting. When everything is right, take the blade out of the plane and run the plane across the spinning flake, holding it tight against the contend. Plow it around, and make a laissez passer with the other side of the aeroplane against the fence. Repeat until the groove is .003 deep.

I tried this on a junky onetime plane, and when it worked (to my amazement) I tried information technology for existent. Airplane, router, and bit are all doing well.

Gluing the Rod Together

When the strips have been planed to terminal dimension, it is time to glue them together. Initially, I used polyurethane mucilage. It is widely available, affordable, and waterproof. It fills gaps, has a working time of twenty to 30 minutes, and dries the aforementioned color equally bamboo. Unfortunately, 20 to 30 minutes isn't a lot of time when you're trying to clamp up six pieces of bamboo but slightly thicker than the butt cease of a leader. The pieces slipped, slid and twisted equally I worked, and to make a long story short, the polyurethane rods were the ones that became tomato stakes. I employ industrial epoxy now, which is surprisingly friendly– it dries slowly, so if I accept a problem I literally accept hours to solve it.

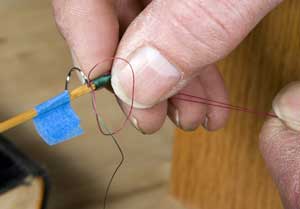

The strips that make upwards a fly rod aren't going to clamp together with even the best clamps, so rodmakers clamp them with a shop-made jig (photos below, designed by Everett Garrison) that binds the pieces together in taut, spiraling wraps of upholstery thread. You apply the glue first, of course, using a toothbrush to spread it over all half dozen strips, which are lined up side-by-side on top of a slice of masking tape. You curl the pieces together, and then run them through the binder. A bulldoze belt made of kite line turns the rod and moves it forward as upholstery thread, fed from above, wraps tightly around the rod.

Making a Garrison Binder

It is hard not to expect at Garrison binder and think of Rube Goldberg, but at heart, information technology's actually a simple automobile. The drive belt — a length of kite cord with the ends tied together — travels up from a weight and pulley to the rod. The belt wraps twice around the rod, and goes down to the drive wheel. From there, the belt travels back to the weight and pulley, back upward to the rod, and so on. Turning the crank on the drive wheel turns the rod and moves information technology from left to right. The rest of the wheels — made from old pulleys — are only there to guide the string. The 2 immediately left of the drive wheel pinch the string against information technology then the chugalug won't slip. The other two wheels guide the string on its trip from the weights, and proceed it from twisting.

The purpose of all this is to wrap upholstery thread around the rod and bind the pieces together. The thread feeds from to a higher place, is tucked under the drive string at the rod, and spirals around the rod every bit it moves.

The base of operations of my folder is made of HDPE, an epoxy resistant plastic that works like wood. You tin also brand the jig out of wood or metal. None of the dimensions are particularly disquisitional. The wheels can get well-nigh anywhere, though the jig does seem to work ameliorate if the drive belt runs at an angle as it approaches and leaves the rod. For meliorate traction, put a condom ring around the drive bike.

The weights are fishing weights, connected to a pulley past a carabiner. I filed a small groove in the face of the pulley so that I could feed the drive belt through it.

Download construction drawings of the Garrison-Rod-Binder

Flatten the Rod

The fishing weights hanging from the drive chugalug make up one's mind the pressure with which the string is applied. On a tip as tiny as this 1, equally I discovered, the weight of anything more than the pulley is enough to snap the rod until yous get a skillful x inches from the tip. At that betoken I add a 12-ounce weight. I use a 16-ounce weight on the butt department. One time the rod is wrapped, you lot straighten out any twists, and then roll it under a lath, a roller, or both, to straighten information technology (photo below). I set it nether weights on the planing form to keep information technology straight while the glue cures. There volition all the same be some minor twists and bends when the mucilage dries, only you lot can straighten them out with gentle estrus from the rut gun.

Stage Iii: Finishing

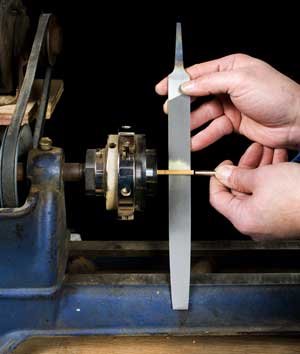

All that remains is putting the ferrules, handle, reel seat and line guides on. Ferrules first: The i.d. of the ferrule is less than the o.d. of the rod, so you file downward the ends as the blank turns on the lathe. You'll need a three- or 4- jawed chuck and a back up to go along the far end the blank from whipping effectually. I made my back up by bolting a piece of plywood to a table saw outfeed stand. Drill a hole in the plywood, line it with something soft (like a cork with a hole drilled in information technology) and so feed the rod through the hole to steady it.

The handle and reel seat get glued on next – get fix-made ones for your first couple of rods. Yous tin larn to brand your ain later.

Finishing, equally a friend observed, is half science and half serpent oil. Garrison hitting upon the method most rodmakers use today. He dipped the rod, narrow end down, into an upright pipe filled with varnish, and pulled it out with a motor running at 1 rpm.

This requires a pretty alpine ceiling. I don't take one, so I began to call up about the last days of each semester in my college woodworking courses, when the shop smelled of Waterlox and Watco. It was the dustiest place on the planet, and withal because we were using oil-based finishes that nosotros wiped off, nosotros could still go a blemish-gratis finishes. So far, I've finished my rods with Birchwood Casey® TRU-OIL® Gun Stock Stop — a pure tung oil that is likewise traditional rod finish. I apply it with a rag, and rub information technology for about five minutes and prepare it aside to dry. If there are any imperfections once the coat dries, I sand them gently out with ane,000-dust paper. Later on three or four coats, the terminate rivals varnish.

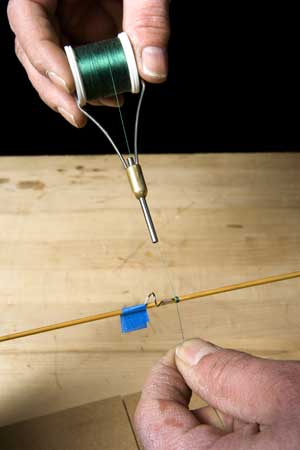

When the stop is dry, you tin put on the guides. The loop at the tip of the rod is epoxied in place. The other guides are held in place by silk thread wrapped around the rod. I've found my fly tying bobbin is the easiest fashion to start the wrap. Once I've started the wrap, I run the thread through the middle of a book to create some drag, and plough the rod to wrap the guide.

If y'all started in the fall, and you take made no tomato stakes and started no fires, it volition probably exist early January by the time you apply the several coats of varnish that hold the silk thread in place. Around here, information technology will be a couple of more than weeks before the blue-winged olive hatch. See you on the stream.

Source: https://www.woodworkersjournal.com/how-to-make-a-bamboo-fly-fishing-rod/

0 Response to "How To Build A Fly Rod"

Post a Comment